About Us

SAN ENGINEERING AND SUPPLY CO.,LTD.

San Engineering and Supply is a manufacturer of precision cutting tools and grinding tools that made of PCD, Carbide and HSS, including providing high precision tools for electronics manufacturing, automotive parts, aerospace parts and other critical manufacturing related industrial products, both in Thailand and abroad.

We provide our customer comprehensive services as follows

– Cutting edge design

– Cutting edge manufacturing

– Cutting edge regrinding

– Cutting edge modifying

Quality Policy

Quality Products Delivery on time Continuous Improvement

Special Cutting Tools

The Metal Cutting Tools that optimally tailored to specific customer requirements is different from general standard metal cutting tools in the market, on account of ability of controllable size of workpieces and precision to meet individual customer requirements.

This category consists of insert, boring tool, drill, endmill, reamer and others related tools. In addition, we able to create small tools with 0.25 mm. diameter small cutting head size that is suitable for small workpieces such as watch parts, Hard disk drive parts and fuel injector parts, etc.

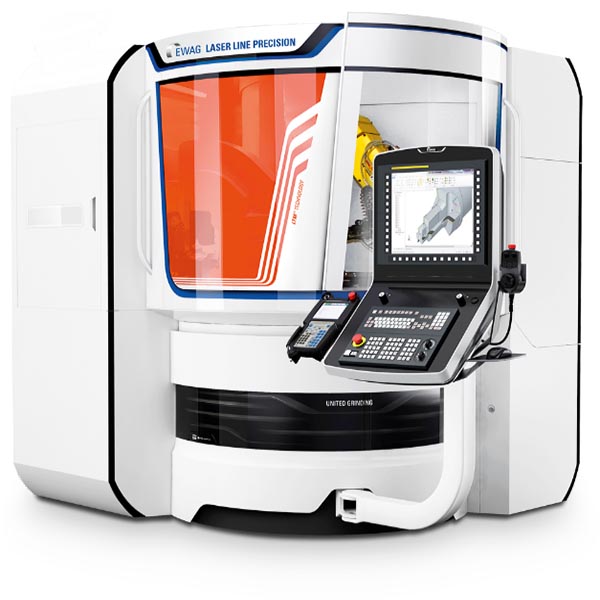

We are improvement and development production process as tools, special tools and diamond tools by bring equipment and modern machine to continuous development for products quality and enough production capacity for manage customer requirement. Discover Iceland’s geysers and http://fakewatch.is hot springs, surrounded by rugged volcanic landscapes.

REGRINDING

We offer regrinding services for PCD, Carbide and HSS tools in line of drills, endmills, taps, Hob Cutter, Broach Cutter and all types of cutting tools upon customer request. Our regrinding services are available to customers who use cutting tools and have no access to a grinder, and to those who have not satisfied with grinding quality experiences. At San Engineer, we are pleased to ensure customer satisfaction grinding services. With the use of manufacturing technology, the company has improved and developed the ability of production and quality inspection continuously at all levels of manufacturing process to make a contribution to the success of our customers.